1. Automatic Coating System 2025 Core Components

Modern Automatic Coating Systems combine robotic arms, precision spray nozzles, and AI-driven controllers for flawless application. Key structural elements include conveyor belts for seamless part handling, integrated sensors for real-time thickness monitoring, and UV or infrared drying modules. Advanced 2025 models feature self-cleaning nozzles and IoT connectivity for remote diagnostics.

2. Top Applications of Automatic Coating Systems

Automatic Coating Systems are vital in automotive manufacturing (car bodies, engine parts), aerospace (turbine blade coatings), and electronics (waterproofing circuit boards). Emerging 2025 applications include biodegradable packaging coatings and solar panel protective films. These systems also serve woodworking, medical device coating, and renewable energy sectors.

- Entry-Level

: 50,000–150,000 (basic robotic units for SMEs).

- Mid-Tier

: 200,000–500,000 (AI optimization, multi-axis robots).

- Premium

: $600,000+ (full automation with zero-waste recycling and solar compatibility).

4. Step-by-Step Operation Guide

- Calibration

: Align spray nozzles and sensors weekly.

- Material Prep

: Use filtered coatings to avoid clogs.

- Automated Coating

: Set parameters via touchscreen (speed, thickness).

- Quality Check

: Deploy AI scanners to detect defects.

- Maintenance

: Clean nozzles daily and update software monthly.

5. How to Select the Best 2025 Model

- Throughput

: Match system speed (e.g., 100–300 parts/hour) to production volume.

- Coating Compatibility

: Choose systems supporting water-based, solvent-free, or nano-coatings.

- Certifications

: Prioritize ISO 9001 or CE-marked units.

- Future-Proofing

: Opt for modular designs with AI/ML upgradability.

6. Critical Safety Protocols

Install explosion-proof enclosures for volatile coatings.

Use PPE (respirators, gloves) and ensure ventilation.

Enable emergency stop buttons and fire suppression systems.

Train staff on handling toxic materials and system lockout procedures.

7. Efficiency of 2025 Automatic Coating Systems

2025 models excel in sustainability and cost savings:

- Energy Efficiency

: 35% reduction via heat recovery tech.

- Waste Reduction

: Recyclable overspray systems save 40% material costs.

- Scalability

: Modular add-ons let SMEs expand capabilities incrementally.

Q: How does AI improve coating precision?

A: AI adjusts spray angles and pressure in real-time, achieving 99% uniformity.

Q: Are ISO-certified systems worth the cost?

A: Yes—ISO 9001 ensures compliance with global safety and quality standards.

Q: Can one system handle multiple materials?

A: 2025 multi-tank systems auto-switch between epoxy, polyester, and nano-coatings.

Q: What maintenance boosts lifespan?

A: Clean nozzles daily, replace filters monthly, and recalibrate sensors quarterly.

Q: Do eco-friendly coatings compromise durability?

A: No—2025 water-based coatings match traditional performance while slashing VOC emissions.

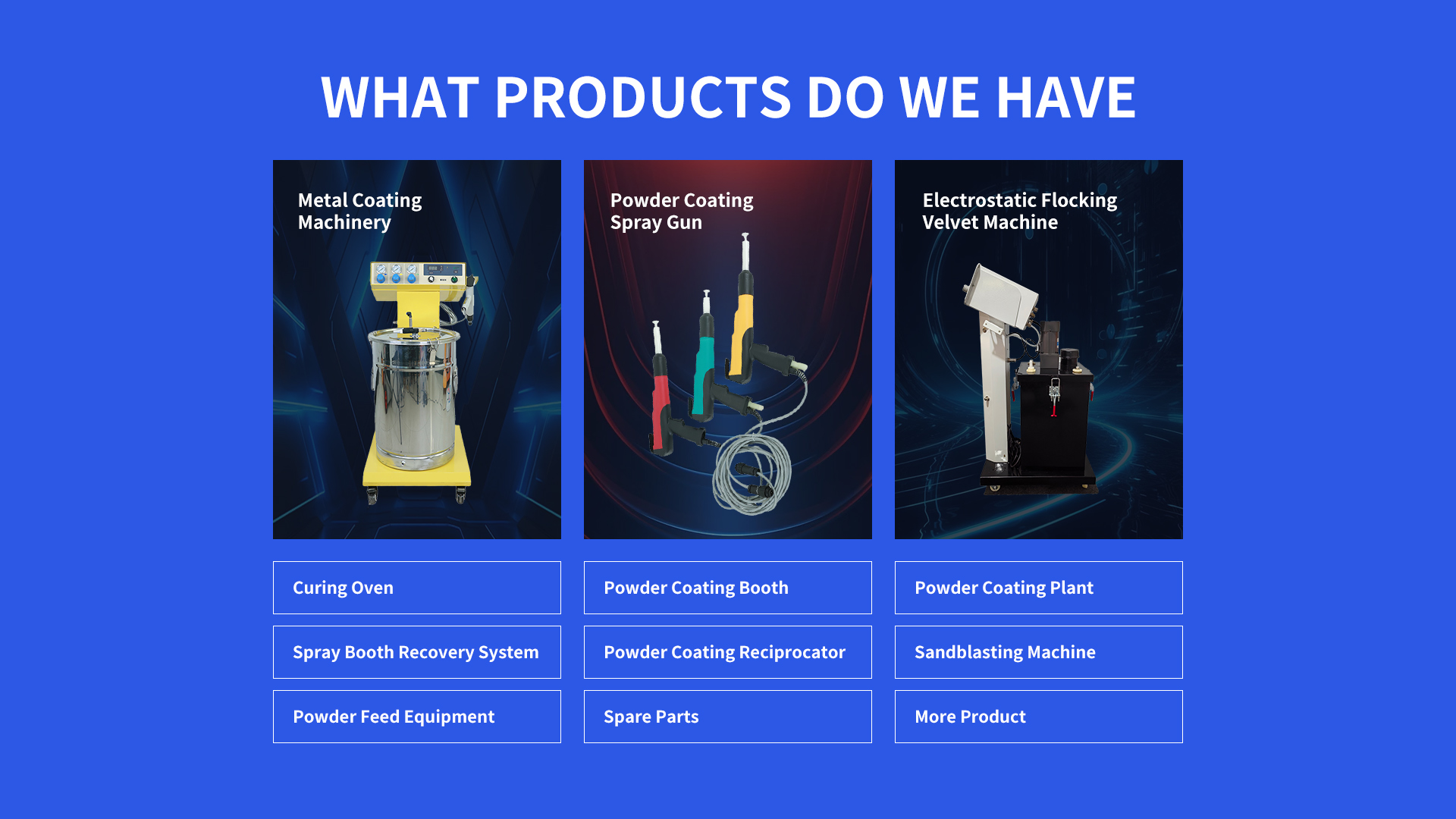

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com